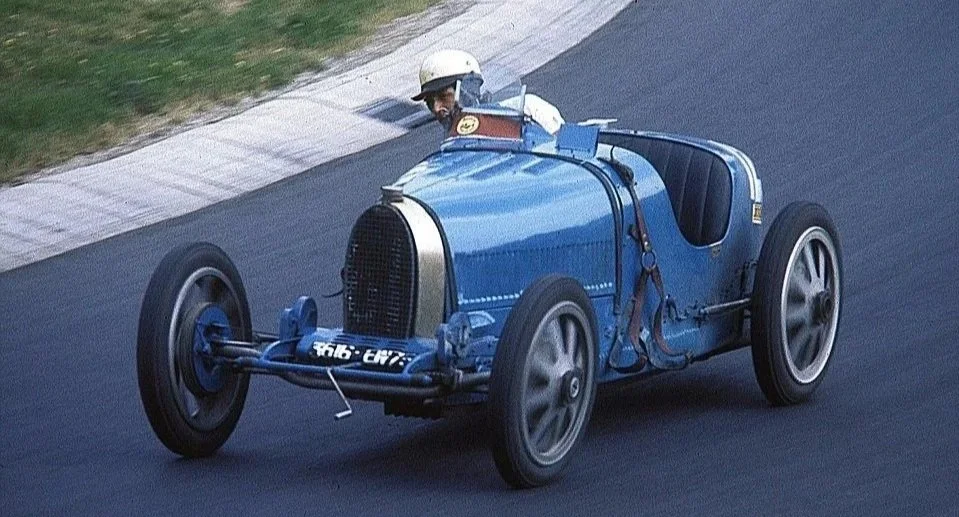

Manufacturing and Designing a Toy Bugatti

Start-to-end design, manufacturing and assembly of a 1920s Bugatti Type 35

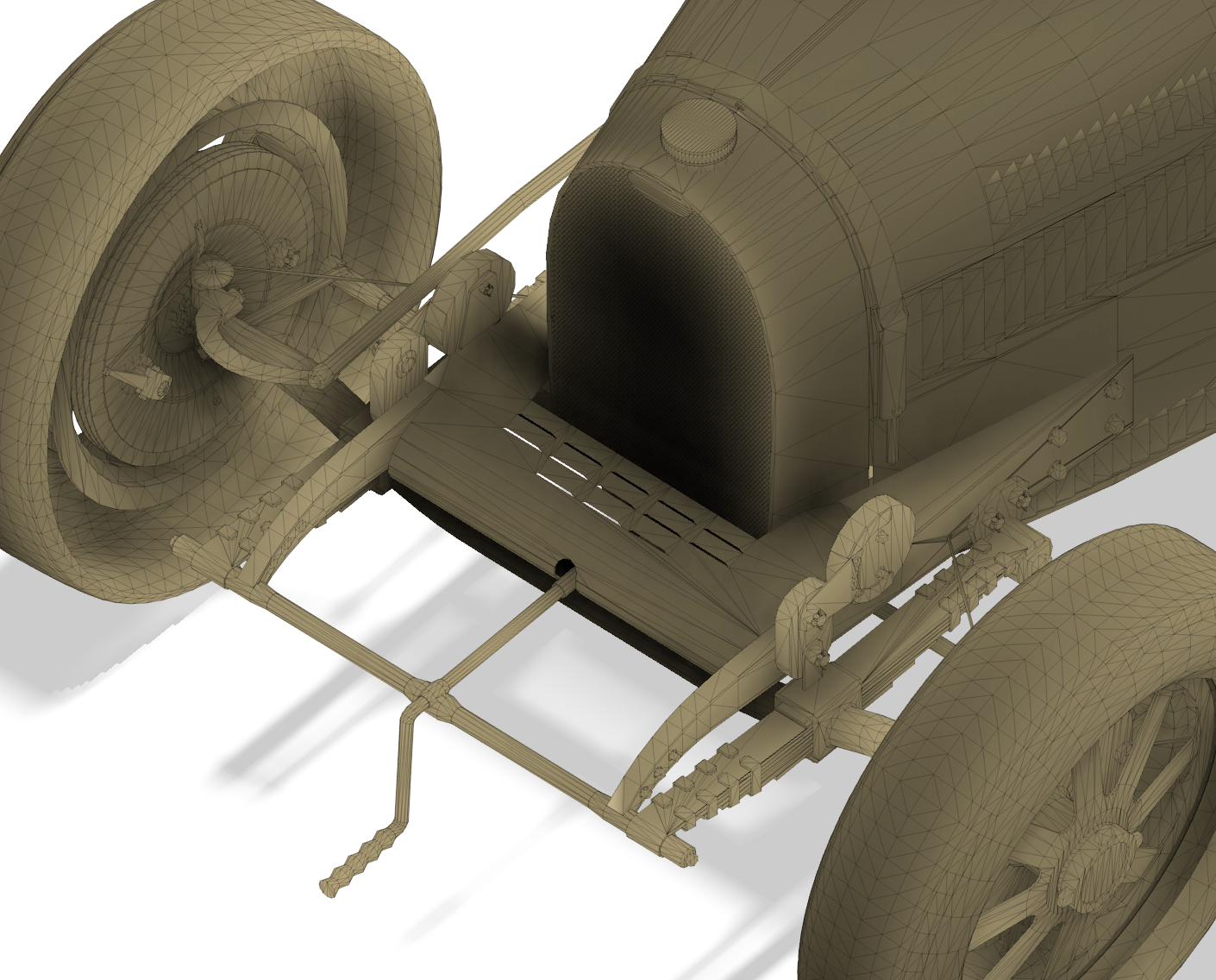

Fig. Detailed CAD via Fusion360

The Problem

Fabricate a durable, functional toy car within strict material, tooling, and process constraints

Translate detailed CAD geometry into manufacturable molds and tooling

Execute multiple manufacturing processes + maintain dimensional accuracy for fit

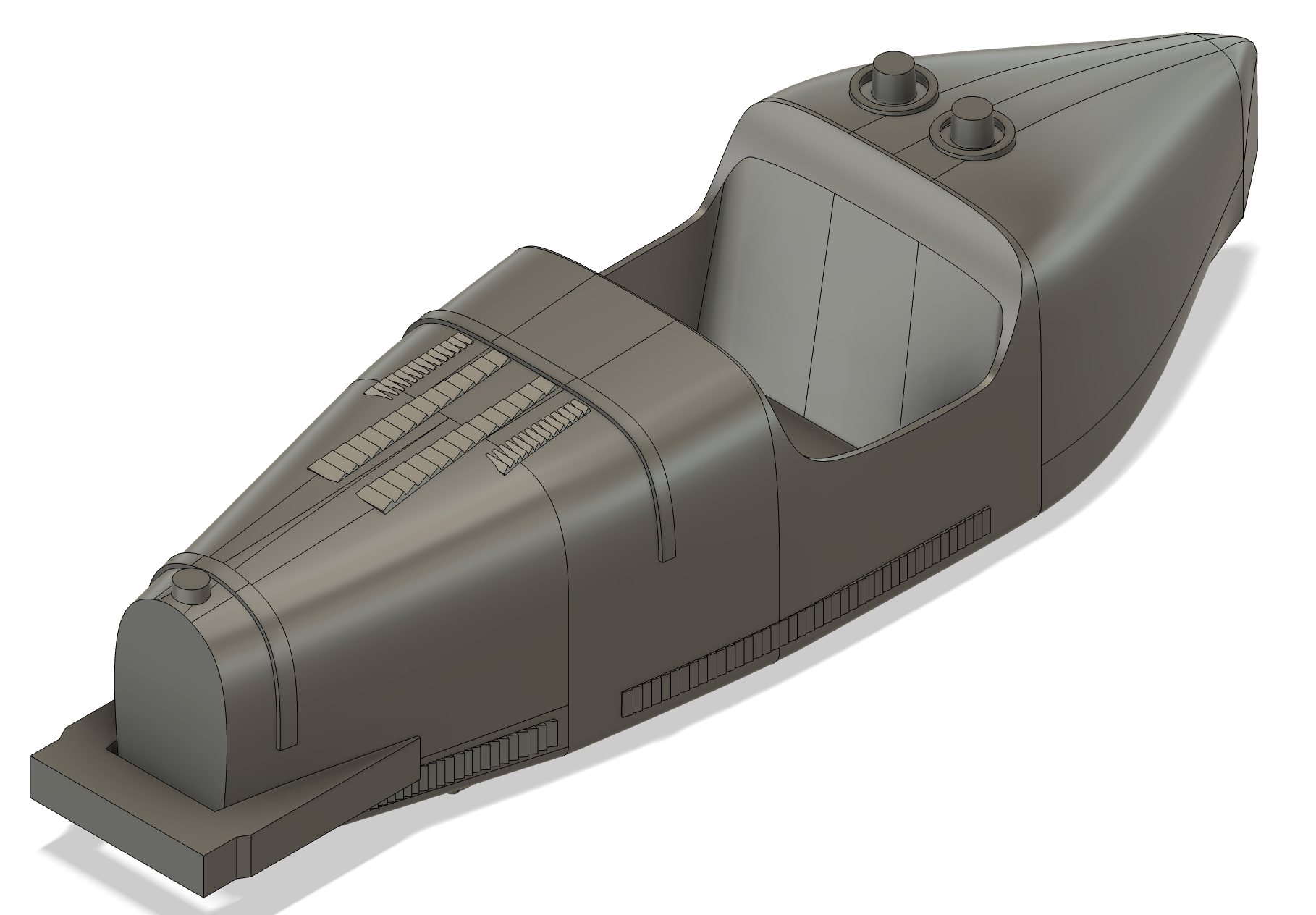

Fig. CAD model of the vehicle body

The Approach

Modeled the car body and components in Fusion 360

Used the cavity feature to create a 3D printable mold.

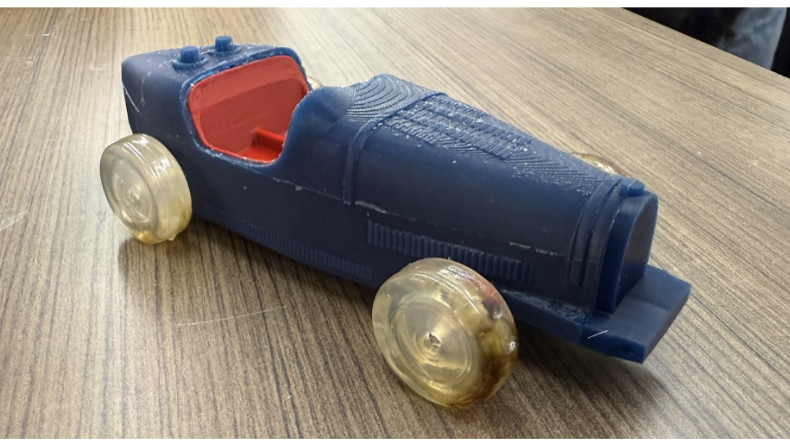

Casted the vehicle body with Silicone

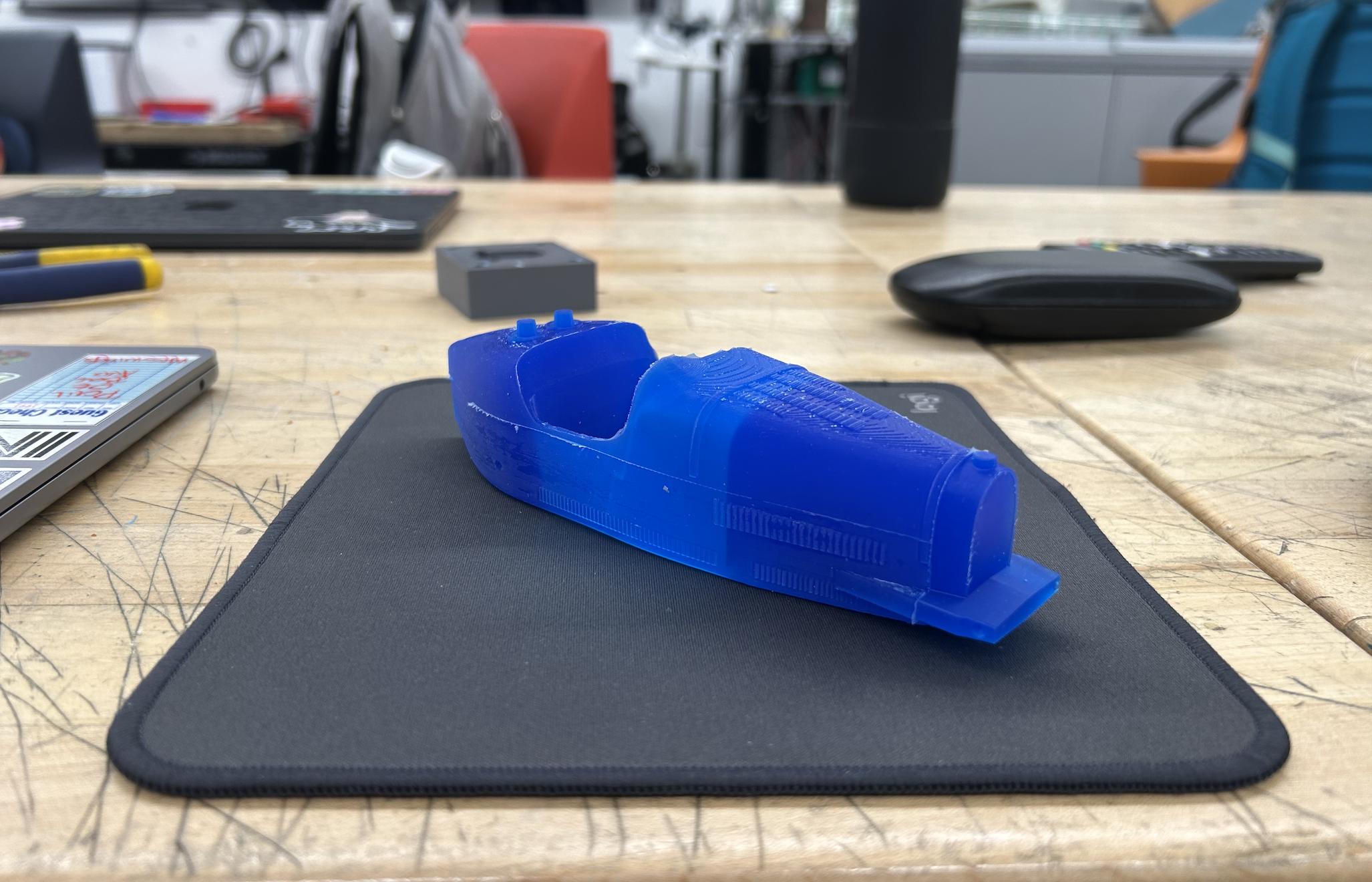

Fig. Final silicone casted vehicle body

Fig. CAM milling of wheel mold

Fig. 3D printed mold for casting

Fabricated molds using CAM milling for steel tooling.

Used the steel mold to inject plastic and create wheels

Fig. Final steel mold used for injection molding

Produced and evaluated multiple prototypes to identify casting defects, mold leakage, air entrapment, and structural issues. Refined geometry, tooling, and assembly features based on observed failures.

The Result

Successfully created molds and casted with various materials

Learned CAM techniques to create steel molds for DIY injection molding

Final model selected as Mechanical Engineering Department exemplar