Regenerative Knee Implant Research

As a researcher at the Columbia Musculoskeletal Biomechanics Lab, I assisted in the development of a knee implant for patients impacted by osteoarthritis (OA).

The Problem

The mechanical properties of novel, 3D-printed implant materials were not well characterized

Implant components experience multiple loading modes, requiring validation under compression, tension, and torsion

Mechanical behavior depends strongly on geometry, material choice, and printing parameters, making performance difficult to predict

Reliable experimental data was needed to inform design decisions and guide future implant development

Fig. 3D modeling via 3D Slicer

The Approach

Computational Modeling

Built 3D models of tibia and femur geometries using 3D Slicer, Blender, MeshMixer, and SolidWorks, and performed finite element analysis (FEBio) to study stress distribution and mechanical behavior under physiological loading

Fig. Surface smoothening via Meshmixer

Fig. Geometric manipulation via SolidWorks

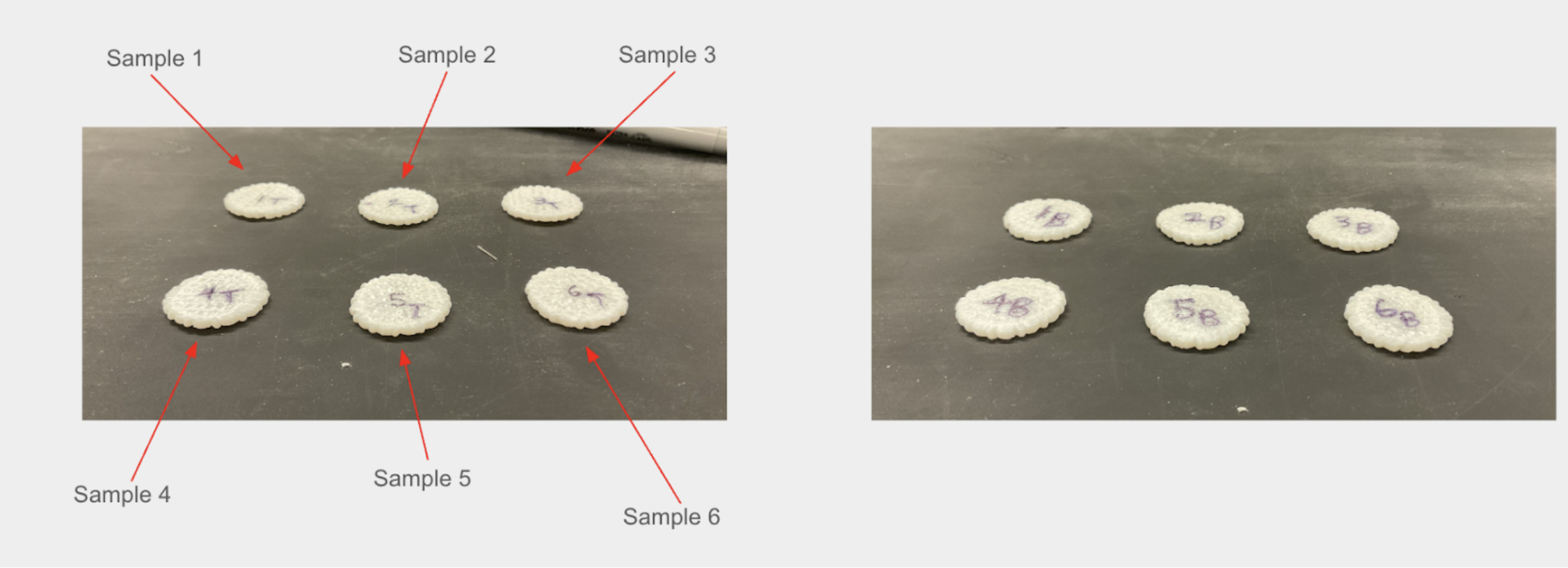

Material Characterization

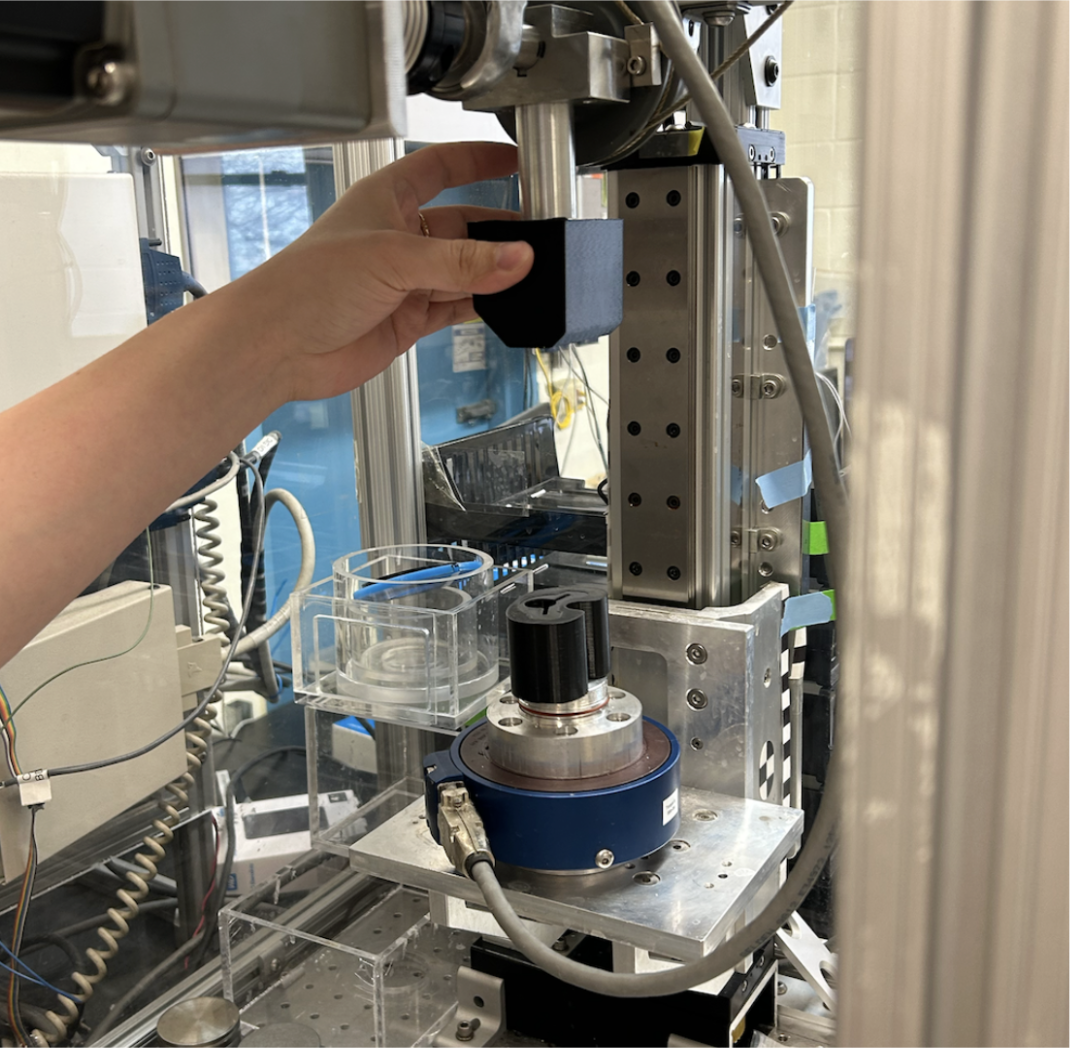

Conducted mechanical testing on 3D-printed samples to quantify strength, stiffness, and failure behavior of implant materials

Tested implant scaffolds under compression, tensile, and torsional loading using Instron systems to reflect physiologically relevant loading conditions

Varied geometry, material selection, and printing parameters to understand how each factor influenced mechanical response and failure modes

Fig. Compression testing samples via Instron to characterize material properties

Testing Hardware Design

Designed and iterated a multi-part, 3D-printable mechanical testing fixture in SolidWorks to isolate and load parts and minimizing unwanted degrees of freedom

Contributed to the design and refinement of a friction testing rig for characterizing the coefficient of friction

Fig. Friction tester with 3D printed rigs

The Impact

Produced reliable experimental data validating implant mechanical performance

Improved test repeatability through custom rig and fixture design

Informed geometry and material decisions with quantified mechanical behavior

Executed 250+ mechanical tests (compression, tensile, and torsion) on 3D-printed implant scaffolds

Designed and fabricated custom test hardware (5+ fixtures and jigs)