Columbia Formula Racing

Aero-Based Cooling via Nosecone Design

The Problem

Accumulator overheating during endurance runs

Cooling limited by poor airflow quality under the car

Existing nosecone caused flow separation and vortex losses

Under-floor air speed too low for effective convective cooling

The Challenge

Deliver clean, high-velocity airflow to the accumulator cooling surface

Improve cooling without adding fans or increasing drag

Maintain aerodynamic stability and rules compliance

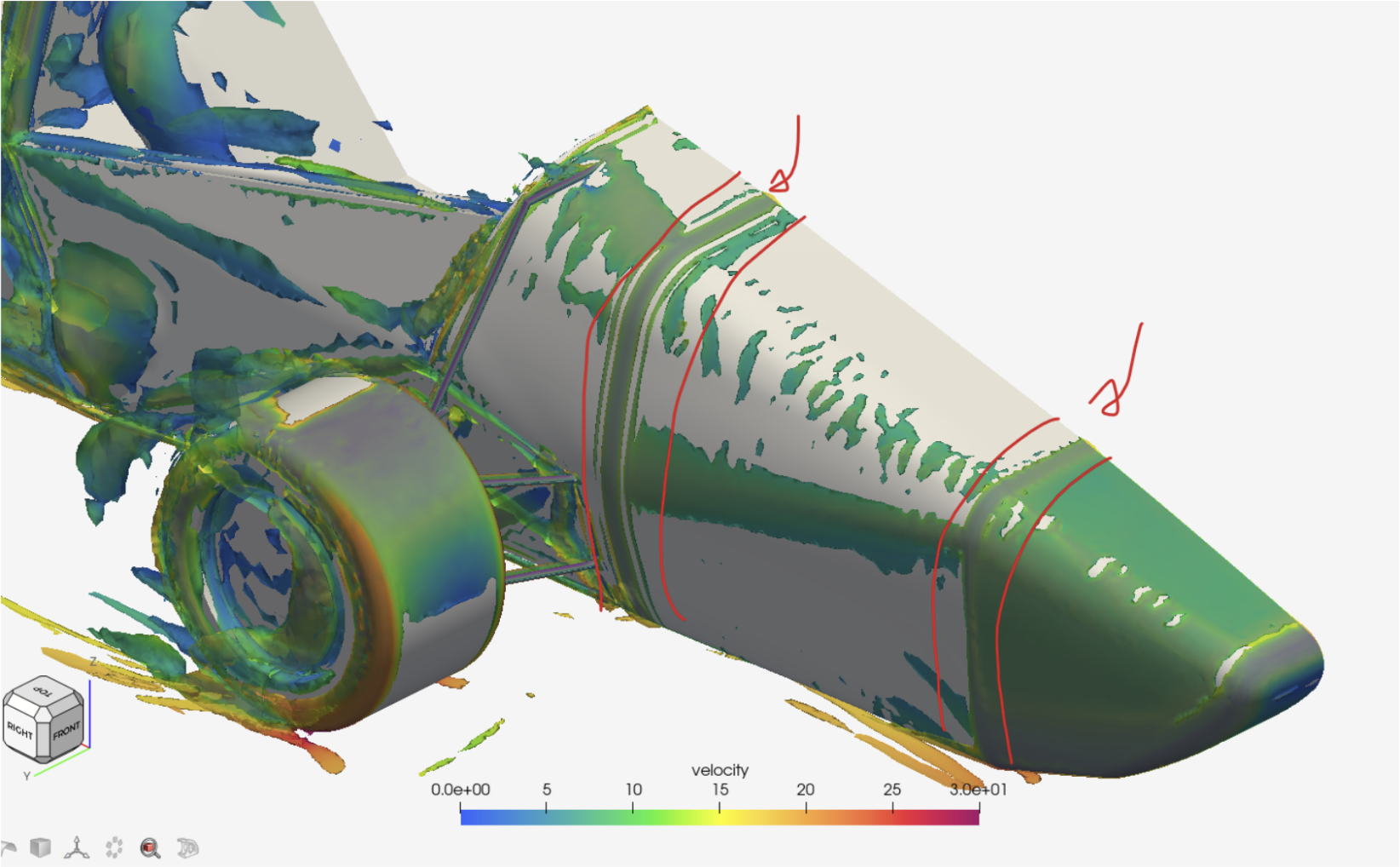

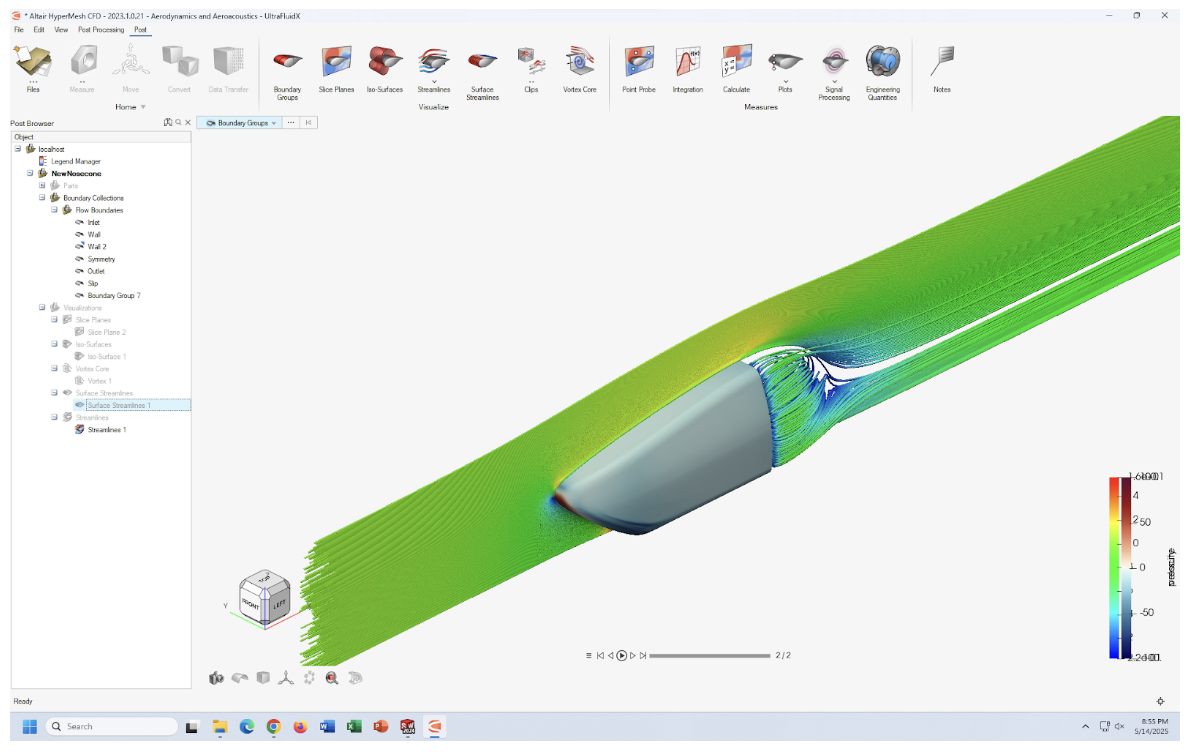

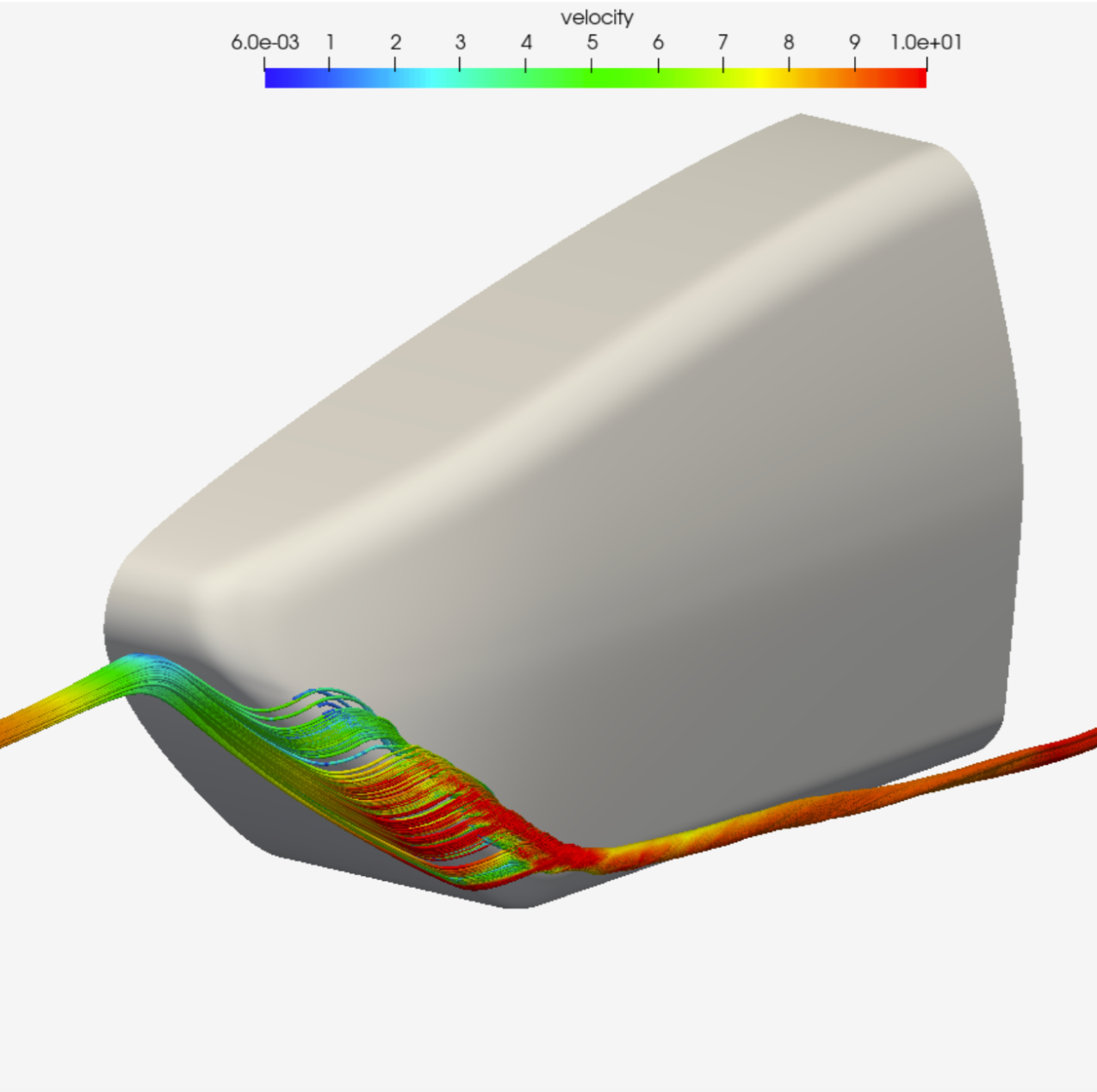

CFD: Vorticity shed by the previous nosecone, colored by velocity (m/s).

Note: Red annotations mark major sources of loss on the nosecone caused by inadequate geometry continuity

The Solution

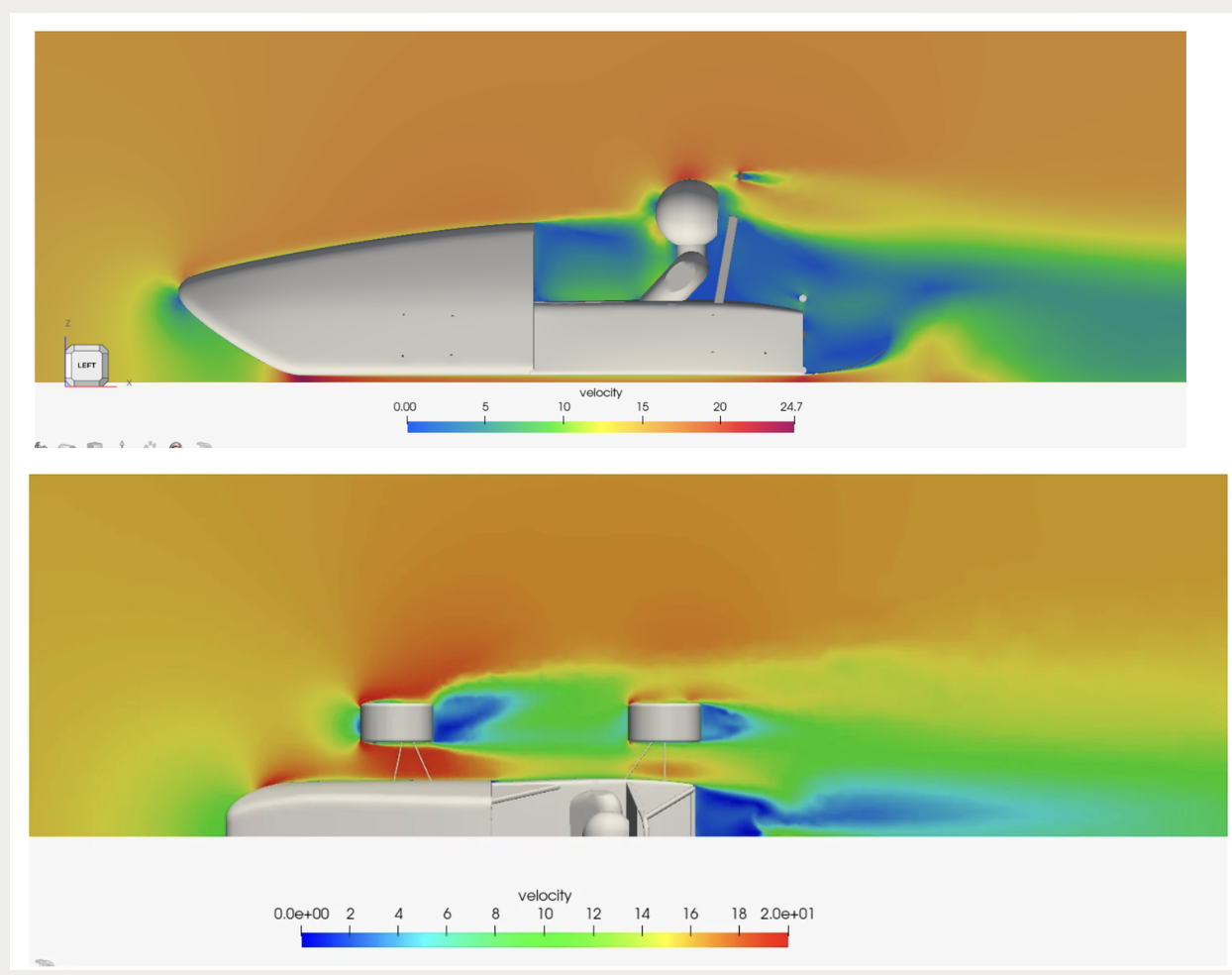

Fig. initial CFD to understand airflow behavior and guide design choices

Define Requirements

Estimated thermal load from the accumulator and identified air-side convection as the bottleneck

Defined airflow requirements: high-velocity, stable under-floor flow to reduce thermal resistance

Established aerodynamic constraints from FSAE rules and packaging limits

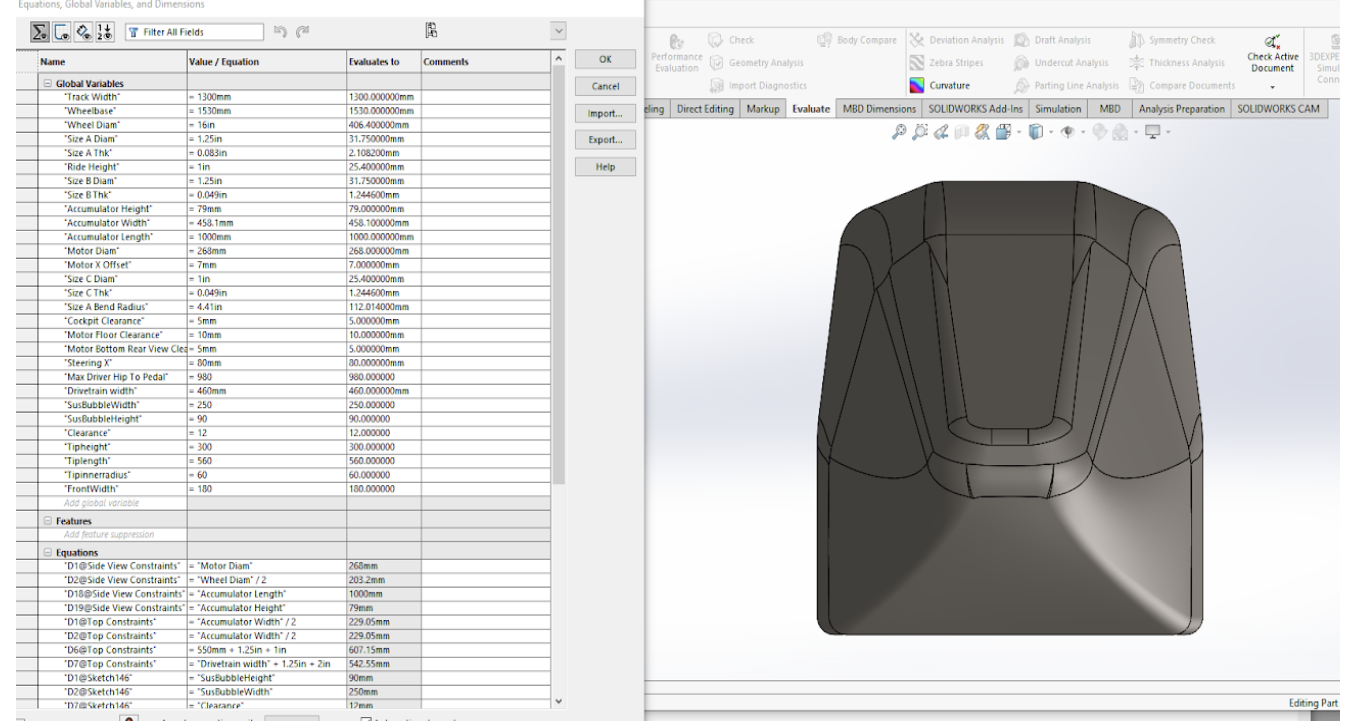

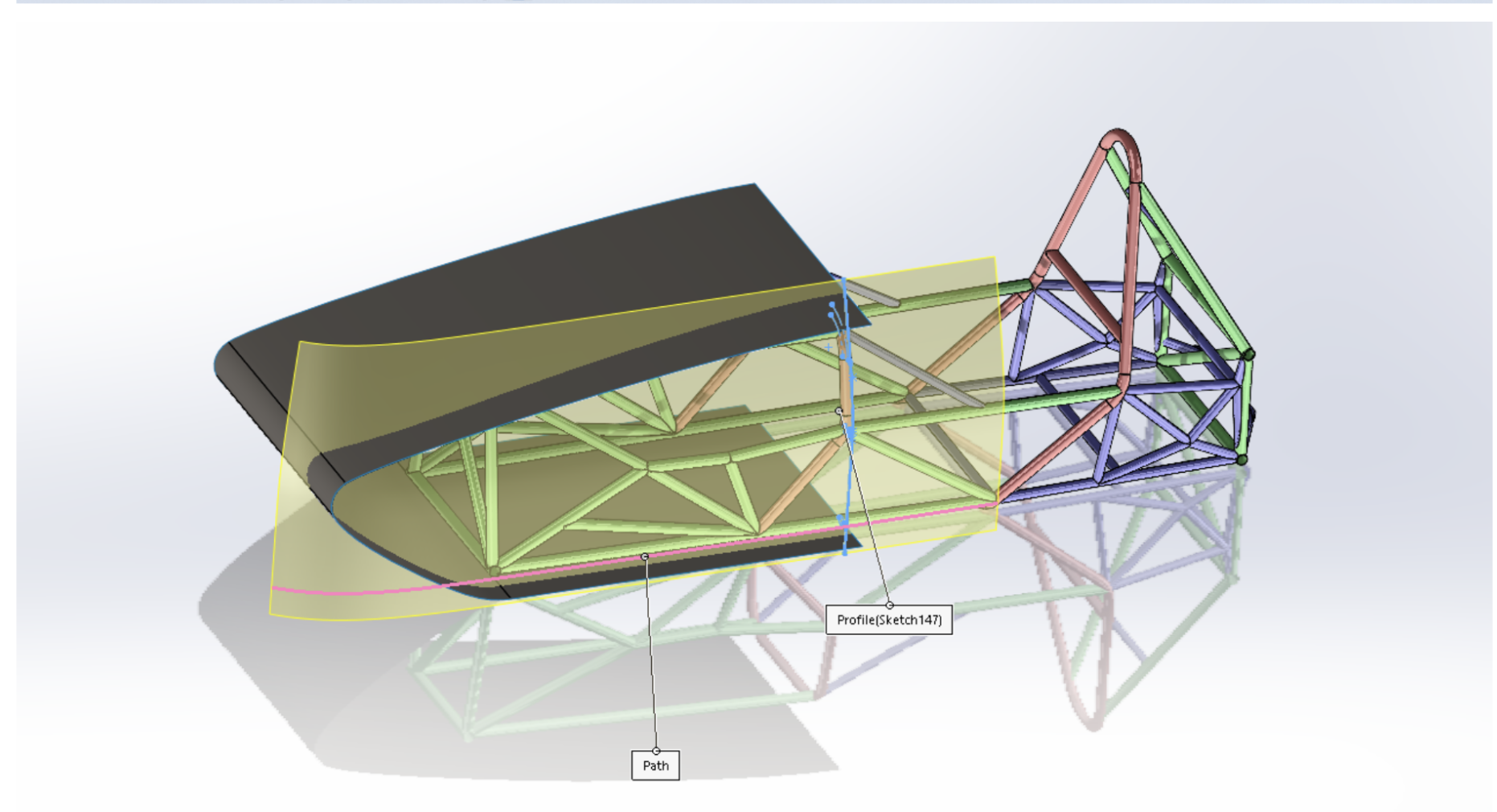

Fig. Parametric CAD of the Nosecone, variable geometry

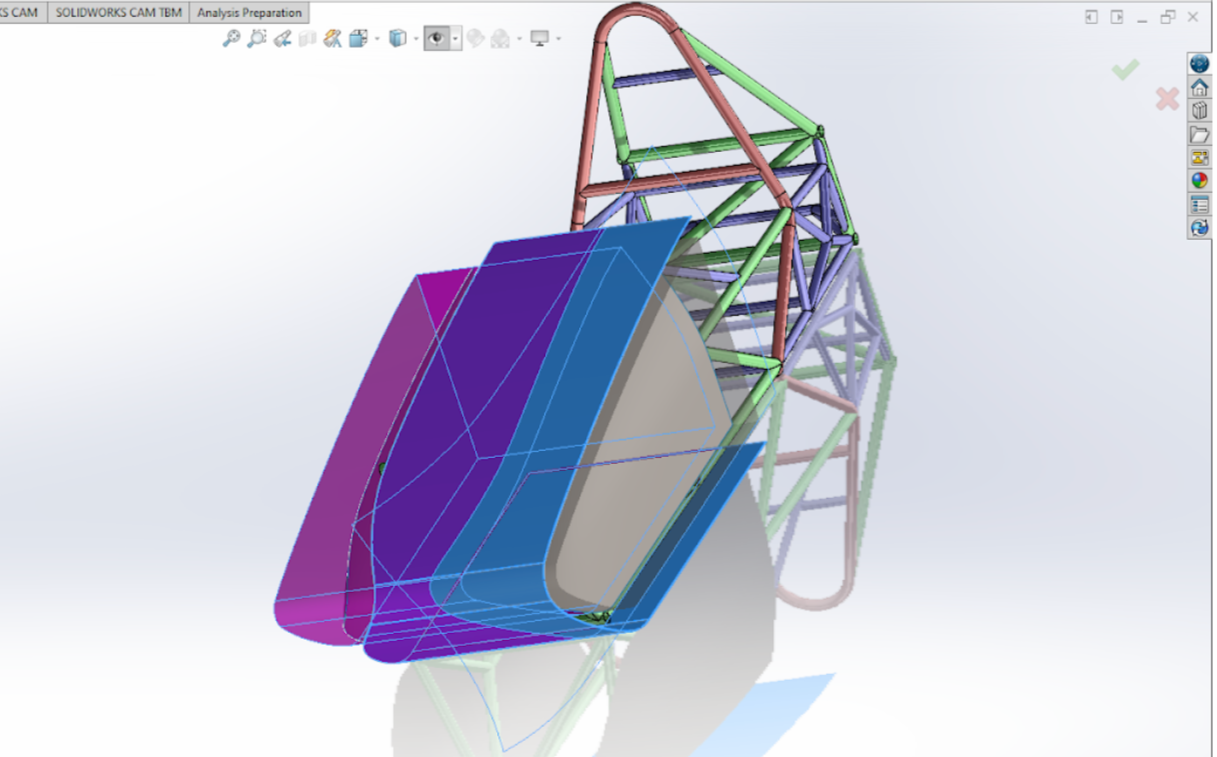

Fig. Surface Modeling, Nosecone

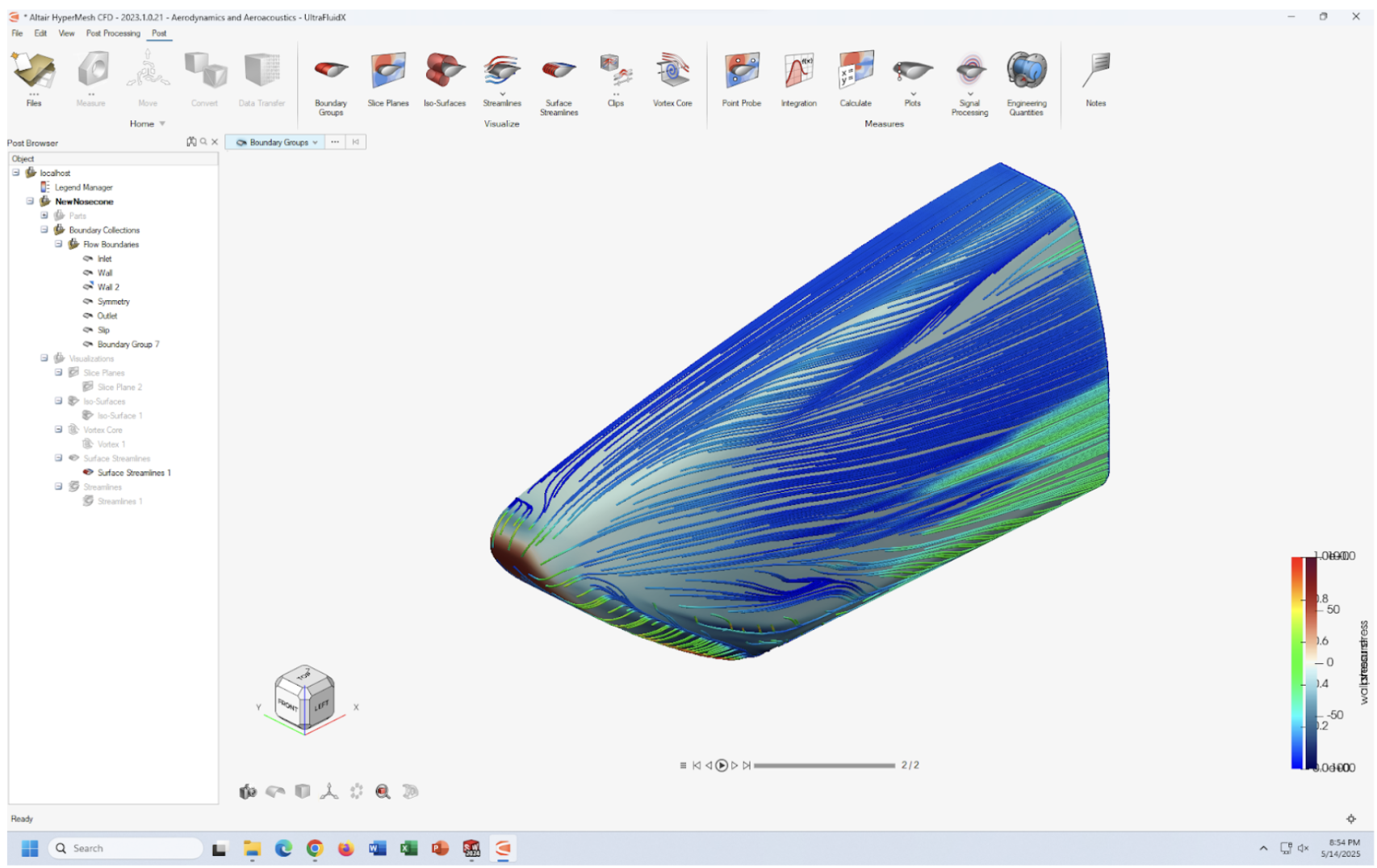

Iterative CFD-Driven Refinement

Used CFD to evaluate velocity fields, pressure distribution, and vorticity

Identified and eliminated geometry-induced flow losses

Tuned nosecone geometry to generate a controlled vortex for floor sealing

Iterated design until airflow to the undertray was clean, stable, and repeatable

Fig. CFD, pressure gradient

Parametric Nosecone Design

Built a fully parametric SolidWorks model

Key variables included tip height, width, and inner radius

Used surface modeling with G2 continuity to maintain smooth airflow and prevent boundary layer disruption

Fig. CFD, surface streamlines

The Impact

Thermal Performance

Significantly increased mass flow to the accumulator cooling zone

Enhanced convective heat rejection by delivering higher-velocity airflow to cooling surfaces

Aerodynamic Performance

Eliminated geometry-induced flow losses at the nosecone

Generated a controlled vortex for effective floor sealing

Improved under-floor airflow quality and diffuser performance

System-Level Impact

Increased under-floor downforce (~10%), improving aerodynamic stability

Delivered cleaner, more predictable airflow to downstream aero components

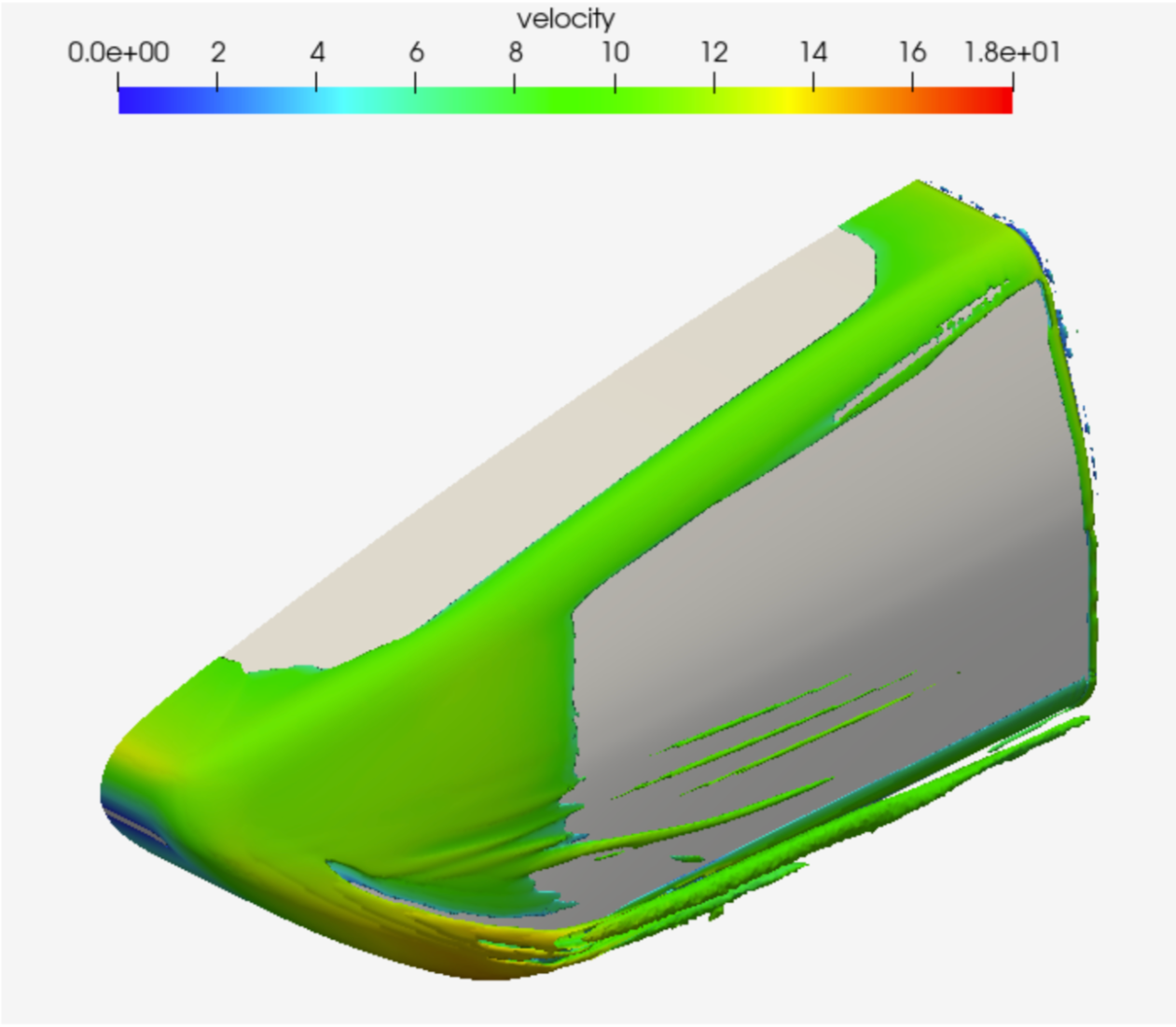

Fig. CFD, Isosurface for a curl of 500Hz, colored by velocity. Velocity is given in m/s.

Fig. Velocity (m/s) streamlines highlighting the Y320 vortex

Conclusion

In stark contrast to the previous nosecone, vortices are well-managed with no major geometry-induced losses

A strong, controlled vortex is intentionally shed from the bottom of the nosecone at y = 320 mm (Y320 vortex)

The Y320 vortex seals the under-floor region, preventing external turbulent flow from intruding into the accumulator cooling zone

Controlled vorticity cleans up downstream tire wake, improving diffuser flow quality

Overall, the redesigned nosecone produces purposeful, stable vorticity rather than chaotic losses, resulting in improved aerodynamic and thermal performance